What is Supply Chain Management? Strategies, Technologies, and Best Practices

Supply chain management works like a central nervous system for modern businesses, connecting different parts to work together toward a single goal. The efficiency of each process—from procurement to logistics—determines customer satisfaction. This guide unpacks what supply chain management is all about, its advantages, and the main challenges that demand smart solutions.

Continue reading to explore:

- Supply chain management definition

- The importance of supply chain management

- Challenges and benefits of supply chain management

- Supply chain management case studies

What is Supply Chain Management?

Supply chain management is the process of planning and coordinating activities related to sourcing, procurement, production, and logistics. Its aim is to optimize the flow of goods, information, and finances from suppliers to customers, ensuring smooth collaboration and enhancing overall efficiency.

How Does Supply Chain Management Work?

- Planning: Forecast demand, set production goals, and determine resource requirements. Companies plan their inventory levels, production schedules, and logistics strategies to meet customer demand while minimizing waste and costs.

- Sourcing: Select suppliers who provide the raw materials or components needed for production. Evaluate them based on cost, quality, reliability, and delivery timelines. Effective supplier management ensures a steady flow of materials into the production process.

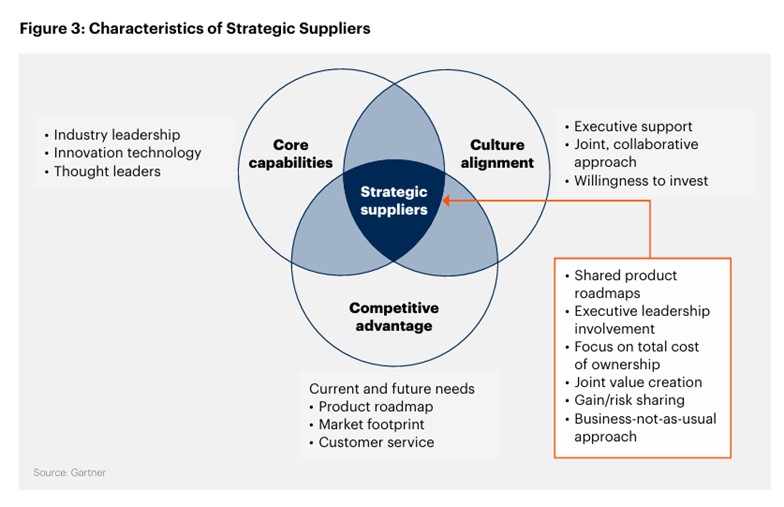

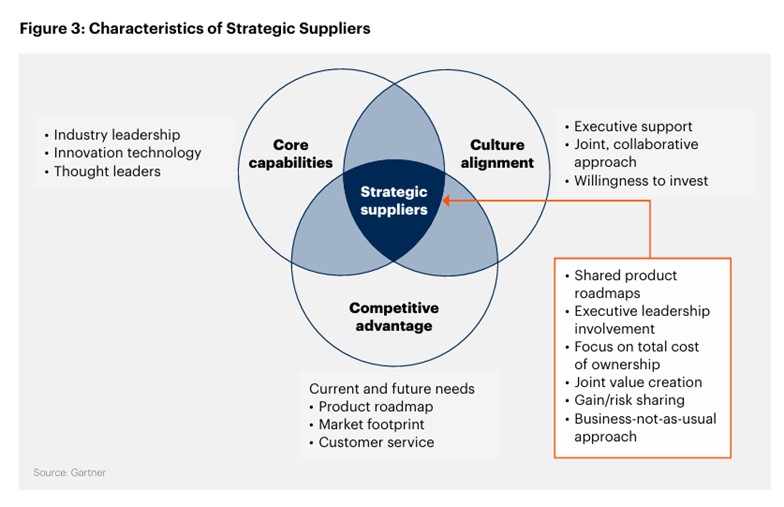

Source: Gartner, 4 Ways to Better Manage Your Complex Supply Base - Manufacturing/Production: SCM oversees how raw materials are transformed into finished products, ensuring production runs efficiently and meets quality standards. This includes managing production schedules, labor, machinery, and inventory to balance costs and demand.

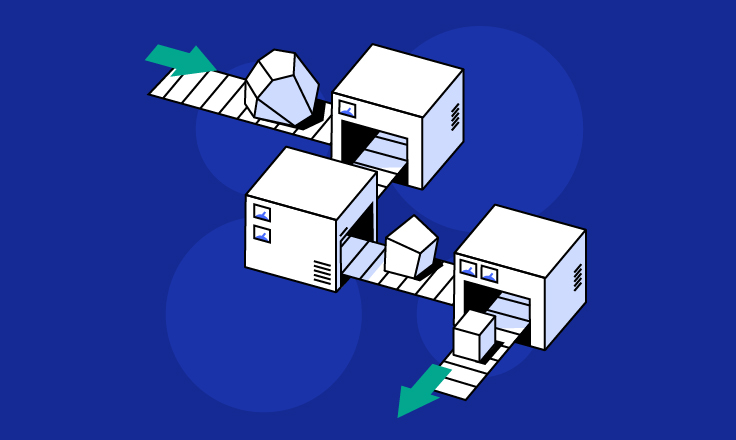

- Logistics: It includes inbound logistics (transporting raw materials to production facilities) and outbound logistics (shipping finished products to customers). SCM optimizes transportation routes, warehousing, and distribution to ensure timely delivery at the lowest possible cost.

- Inventory Management: Maintain a balance between having enough stock to meet demand and avoiding excess inventory that ties up capital. Advanced inventory management techniques, like just-in-time (JIT), help optimize stock levels.

- Information Flow: Information between suppliers, manufacturers, and distributors must flow seamlessly. Data on sales, inventory levels, and customer demand are shared in real time to adjust plans and avoid disruptions.

- Customer Service and Returns: Once products reach customers, SCM ensures customer satisfaction and manages returns. Reverse logistics, which deals with the return and recycling of goods, is also a critical component of the supply chain.

- Continuous Improvement: Through data analysis and new technologies (such as AI and automation), companies can continuously refine their supply chain operations for better performance.

Why is Supply Chain Management so Important?

Supply chain management is the foundation of modern retail. It ensures the smooth and efficient flow of goods, services, and information from suppliers to customers. It helps businesses optimize operations, reduce costs, and meet customer demands.

6 Benefits of Supply Chain Management

1. Cost Reduction

Supply chain management streamlines processes like procurement, production, and transportation, reducing operational costs. Thanks to SCM optimizing inventory levels, automating tasks, and improving logistics, businesses can lower waste and achieve significant savings.

2. Efficiency Improvement

SCM enhances overall efficiency by coordinating various supply chain activities. Automation, real-time data, and advanced planning tools reduce delays, optimize resources, and ensure products move smoothly from suppliers to customers.

3. Improved Customer Satisfaction

Effective SCM ensures timely delivery, better product availability, and improved service quality. By meeting customer demands consistently and efficiently, businesses enhance customer loyalty and satisfaction.

4. Enhanced Collaboration

SCM fosters better communication and collaboration between suppliers, manufacturers, and distributors. This integrated approach allows for faster problem-solving, smoother operations, and stronger partnerships throughout the supply chain.

5. Increased Profitability

Optimized supply chain operations lead to cost savings, improved productivity, and reduced time to market. This directly increases profitability by lowering expenses while maintaining high-quality products and services.

6. Better Risk Management

SCM helps identify potential risks, such as supply shortages or transportation disruptions, and develop contingency plans. With better visibility across the supply chain, businesses can proactively mitigate risks and reduce the impact of unforeseen events. 79% of supply chain professionals have implemented dashboards for end-to-end visibility.

Main Components of Supply Chain Management

Infrastructure

Supply chain infrastructure consists of the physical and organizational structures that support the movement of goods and information. This includes facilities such as warehouses, distribution centers, and transportation networks.

Processes

Supply chain processes encompass the series of steps that transform raw materials into finished products and deliver them to customers: sourcing, procurement, production, inventory management, and logistics. Effective process management ensures that every step is optimized for efficiency, cost-effectiveness, and quality control.

Technology

Advanced tools like automation, data analytics, and real-time tracking help streamline supply chain operations. One key technology is Electronic Data Interchange (EDI) systems, which facilitate the automated exchange of business documents between partners. EDI ensures that orders, invoices, and shipping information are communicated seamlessly, reducing errors, accelerating transactions, and improving overall supply chain efficiency.

Effective Supply Chain Management Features

Integration and Visibility

Effective supply chain management relies on seamless integration across all parts of the supply chain, from suppliers to manufacturers, distributors, and customers. Visibility ensures that all stakeholders have access to real-time data on inventory levels, order statuses, and demand forecasts. This transparency allows for proactive decision-making and efficient management of resources.

Collaboration and Coordination

Strong communication and coordination between suppliers, manufacturers, and logistics partners help prevent disruptions, resolve issues quickly, and improve efficiency. Effective collaboration fosters a shared understanding of goals, ensuring everyone works together to optimize the entire supply chain.

Agility and Responsiveness

An agile supply chain is one that can quickly adapt to changing market conditions, customer demands, or disruptions. Flexibility in processes, fast decision-making, and the ability to reconfigure supply chain operations allow businesses to respond rapidly to challenges such as unexpected shortages, shifts in demand, or transportation delays, minimizing the impact on operations.

Sustainability and Ethical Practices

Companies are increasingly focusing on reducing environmental impact by minimizing waste, optimizing energy use, and adopting eco-friendly materials. Ethical practices, such as fair labor and responsible sourcing, play a crucial role in creating a sustainable supply chain and building trust and long-term relationships with customers and partners. Supply chain emissions are 11.4 times higher than a company’s direct emissions.

5 Steps of the Supply Chain Management Process

1. Plan

The planning stage involves forecasting demand, setting production goals, and developing strategies for sourcing, manufacturing, and logistics. Companies must carefully plan inventory levels, production schedules, and resource allocation to meet customer demand efficiently while minimizing costs and waste.

2. Source

In the sourcing step, businesses identify and select suppliers for the materials, goods, or services needed for production. This means evaluating supplier reliability, negotiating contracts, and managing supplier relationships. The goal is to ensure a consistent and cost-effective supply of high-quality materials. Only 35% of Chief Product Officers have a working supplier segmentation model.

3. Manufacture

The manufacturing phase is where raw materials are transformed into finished products. It encompasses production scheduling, quality control, and coordination of labor and machinery. Effective management at this stage ensures products are produced on time, at the right cost, and to the required quality standards.

4. Deliver

Logistics involves the transportation of finished products to customers or distribution centers. This step focuses on order fulfillment, warehousing, shipping, and inventory management. Timely and cost-efficient delivery is essential for meeting customer expectations and maintaining smooth supply chain operations.

5. Return

Efficient returns management is crucial for customer satisfaction and maintaining sustainability, as well as minimizing waste or financial losses in the supply chain. This step includes managing returns, repairs, or recycling, known as reverse logistics.

Types of Supply Chain Management

Lean Supply Chain Management

Lean SCM focuses on minimizing waste and maximizing efficiency by optimizing processes and reducing unnecessary steps. The goal is to streamline operations to reduce costs while maintaining high-quality standards. This model relies heavily on JIT inventory systems, ensuring that materials and products arrive exactly when needed, reducing excess inventory and storage costs.

Lean SCM works best in industries with stable demand and predictable production cycles.

Agile Supply Chain Management

Agile SCM emphasizes flexibility and responsiveness, allowing companies to quickly adapt to changes in customer demand, market conditions, or supply chain disruptions. Agile supply chains rely on smaller, more frequent production runs and flexible suppliers who can adjust rapidly to shifts in the market, ensuring that products reach customers quickly even in changing environments.

This model is ideal for industries where demand fluctuates frequently, such as fashion or consumer electronics.

Hybrid Supply Chain Management

Hybrid SCM combines elements of both lean and agile models, allowing companies to balance efficiency with flexibility. Businesses use lean principles to optimize the stable parts of their supply chain, reducing waste and costs, while applying agile strategies to the more dynamic segments, enabling quick adjustments to market changes. Hybrid SCM provides the best of both worlds, offering efficiency without sacrificing responsiveness.

This model is particularly useful in industries with both stable and unpredictable demand patterns.

6 Challenges in Supply Chain Management

1. Demand Fluctuations

One of the biggest challenges in supply chain management is dealing with unpredictable demand. Sudden spikes or drops in demand can disrupt production schedules, lead to inventory imbalances, and result in either excess stock or shortages. Accurate forecasting and flexible supply chain strategies are crucial for managing these changes.

2. Supplier Reliability

Issues such as delayed shipments, inconsistent quality, or supplier bankruptcy can lead to production halts and lost revenue. Building strong relationships with reliable suppliers and diversifying the supplier base can help mitigate these risks.

3. Globalization Issues

Operating in a global market introduces complexities such as longer shipping times, varying regulations, and currency fluctuations. Global supply chains can be affected by geopolitical tensions, trade tariffs, and natural disasters.

4. Regulatory Compliance

Compliance with local, national, and international regulations includes adhering to trade laws, environmental regulations, labor standards, and customs requirements. Failing to comply with regulations can lead to fines, delays, or reputational damage, making it essential for businesses to stay updated on the latest rules and maintain proper documentation.

5. Environmental and Ethical Concerns

There is growing pressure on companies to adopt environmentally sustainable and ethical supply chain practices. Addressing concerns such as reducing carbon footprints, minimizing waste, using eco-friendly materials, and ensuring fair labor practices while maintaining profitability is a challenging balance, but it’s becoming a business necessity.

Only 9% of a McKinsey survey respondents report that their supply chains currently comply with the European Union's Corporate Sustainability Due Diligence Directive, while 30 percent acknowledge that they are lagging or significantly behind in their compliance efforts.

6. Technological Integration

As supply chains become more digital, integrating new technologies such as AI, blockchain, and IoT can be complex and costly. Companies often struggle with implementing these tools effectively or integrating them with legacy systems. Ensuring that technology works seamlessly across all supply chain operations is key to unlocking its full potential and maintaining competitiveness.

Supply Chain Management Across Industries and Borders

| INDUSRTY | KEY CHALLENGES | STRATEGIES | GLOBAL CONSIDERATIONS | TECH INTEGRATION |

| Manufacturing | Supply disruptions, cost management | Just-in-time, lean production | Customs regulations, fluctuating tariffs | Automated advanced analytics |

| Retail | Inventory management, fast delivery | Agile logistics, omnichannel strategies | Global sourcing, peak season logistics | E-commerce platforms, AI analytics |

| Healthcare | Regulatory compliance, emergency readiness | Robust inventory systems, cold chain logistics | Diverse regulatory environments | Electronic health records, IoT |

| Automotive | Supplier coordination, recalls | Integrated supply networks, green initiatives | International regulations, environmental compliance | Advanced robotics, EDI systems |

| Global SCM | Visibility, geopolitical risks | Risk management strategies, supplier diversification | Tariff fluctuations, cultural differences | Blockchain, real-time tracking |

Best Practices in Supply Chain Management

Supplier Relationship Management

Effective communication, collaboration, and transparency foster trust, allowing for better negotiation terms and smoother problem resolution. Regularly assessing supplier performance and providing feedback can help enhance partnerships and drive mutual growth.

Inventory Optimization

Efficient inventory management minimizes costs while ensuring product availability. Employing techniques such as just-in-time inventory, safety stock calculations, and automated inventory tracking can help supply chain professionals maintain optimal stock levels. Regularly analyze inventory turnover rates and demand patterns to adapt your strategy for better efficiency.

Demand Forecasting

Utilizing historical data, market trends, and statistical modeling in demand forecasting helps businesses predict future demand and adjust their procurement and production strategies accordingly. Integrating advanced analytics and machine learning can further enhance forecasting accuracy, leading to improved resource allocation.

Continuous Improvement

Regularly evaluating supply chain processes can identify areas for enhancement. Encouraging employee input and feedback also leads to valuable insights.

Risk Management

- Identifying: Recognize risks such as supplier failures, market volatility, and regulatory changes.

- Assessing: Evaluate the likelihood and impact of identified risks.

- Mitigating: Develop strategies to minimize the effects of risks, such as diversifying suppliers or enhancing safety stock.

- Monitoring: Continuously track risk factors and changes in the supply chain environment.

- Reviewing: Regularly revisit risk management strategies to ensure they remain effective and relevant.

Use of Technology

Implementing systems such as ERP, EDI, and supply chain management software provides real-time insights into inventory levels, order status, and supplier performance. Embrace emerging technologies like AI, IoT, and blockchain to further optimize operations and drive innovation.

Employee Training and Development

Providing ongoing education on industry trends, technologies, and best practices ensures that employees stay informed and adaptable. Encourage cross-functional training to enhance collaboration and understanding among different departments, improving overall supply chain performance.

Successful Supply Chains: Industry Case Studies

Toyota's Lean Manufacturing and JIT System

Toyota's supply chain management is renowned for its pioneering use of lean manufacturing and JIT principles, allowing the company to streamline production and minimize waste effectively. Developed within the Toyota Production System, these principles emphasize reducing inventory costs and only producing what is needed when it's needed.

This approach not only saves resources but also enables Toyota to respond rapidly to changes in customer demand—critical in addressing the unique automotive supply chain challenges of managing complex, high-value parts and assemblies.

Key Success Factors:

- Continuous Improvement (Kaizen): Toyota emphasizes ongoing enhancement in all processes, ensuring adaptability and efficiency.

- Strong Supplier Relationships: Collaborative, long-term relationships with suppliers help ensure reliability and quality.

- Effective Demand Forecasting: By accurately predicting demand, Toyota can better balance production with market needs, reducing excess inventory and stockouts.

Walmart's Efficient Inventory Management

Walmart has revolutionized retail supply chain management through advanced inventory management systems, cross-docking, and real-time data analytics. By implementing cross-docking—a practice that transfers products directly from inbound to outbound trucks without long-term storage—Walmart reduces warehouse costs and speeds up product delivery. Additionally, Walmart uses real-time data analytics to closely monitor inventory levels, enabling quick restocking and aligning inventory with customer demand.

Impact on Retail Efficiency

Walmart’s SCM strategies yield significant benefits, including substantial cost savings and reduced stockouts. With optimized stock levels, Walmart can minimize waste while ensuring that products are available when customers need them. This efficient approach to inventory management improves customer satisfaction and positions Walmart as a leader in optimized, customer-centric retail operations.

Apple’s Global Supply Chain Strategy

Apple's strategy hinges on its right supplier partnerships and selective vertical integration. These allow the company to control critical aspects of production while benefiting from high-quality suppliers. By strategically partnering with top suppliers, Apple ensures access to essential components and technology, supporting both high standards and efficient production for its complex product lines.

Risk Management and Innovation

To mitigate supply chain risks, Apple diversifies its supplier base, maintains rigorous quality control, and actively monitors potential disruptions across regions. By fostering close relationships with key suppliers and embracing innovative production techniques, the company effectively manages supply chain risks while driving continuous improvements in product design and manufacturing.

Lessons Learned from Successful SCM Implementations:

- Use of Technology: Advanced data analytics, real-time tracking, and automation streamline operations and enhance responsiveness.

- Strong Supplier Relationships: Collaborative partnerships with suppliers ensure quality and reliability, minimizing disruptions.

- Continuous Improvement (Kaizen): Embracing ongoing process improvement helps address challenges, optimize efficiency, and adapt to changing demands.

- Risk Management: Proactive risk assessment and mitigation strategies secure supply chain resilience and stability.

- Customer-Centric Focus: Aligning inventory and production with customer needs ensures product availability, reducing stockouts and improving satisfaction.

Incorporating these best practices can elevate your supply chain management by focusing on strategic partnerships, technology integration, and a commitment to continuous improvement. Prioritizing data-driven decisions, strengthening supplier collaborations, and fostering a proactive approach to risk management will help build a resilient, efficient supply chain model that adapts to market demands and enhances customer satisfaction.

Technological Advances and the Future of Supply Chain Management

AI in SCM

Artificial Intelligence is revolutionizing supply chain management by enabling predictive analytics, demand forecasting, and process automation. AI-driven algorithms can analyze vast amounts of data to identify trends and optimize inventory levels. Additionally, AI-powered chatbots and virtual assistants enhance customer service and streamline communication across the supply chain.

Blockchain in SCM

Blockchain technology offers enhanced transparency, security, and traceability within supply chains. By creating a decentralized ledger of transactions, blockchain allows for real-time tracking of products from origin to destination. This technology reduces fraud, improves global compliance, and enables faster dispute resolution. As more companies adopt blockchain, it has the potential to transform supplier relationships and streamline logistics.

IoT in SCM

The Internet of Things connects physical devices and sensors to the Internet, allowing for real-time data collection and monitoring. In supply chain management, IoT devices can track inventory levels, monitor equipment performance, and optimize transportation routes. This data-driven approach improves visibility and enables proactive decision-making, reducing downtime and enhancing efficiency.

Big Data Analytics in SCM

Big Data analytics provides valuable insights into supply chain operations by analyzing vast datasets from various sources. Companies can leverage these insights for demand forecasting, risk assessment, and supplier performance evaluation.

Industry 4.0 and SCM

Industry 4.0 represents the fourth industrial revolution, characterized by the integration of advanced technologies like AI, IoT, and automation in manufacturing and supply chain processes. Embracing Industry 4.0 principles allows companies to optimize resource utilization, improve production schedules, and enhance customer satisfaction.

SCM and the Cloud

Cloud computing is transforming supply chain management by providing scalable, flexible, and accessible solutions. Cloud-based platforms facilitate real-time collaboration among supply chain professionals, improve data sharing, and enable centralized inventory management.

Comarch: Empowering Supply Chain Professionals for Future Success

Today, effective supply chain management is the main difference between merely surviving and thriving in a competitive market. The importance of SCM, its challenges, and case studies illustrate how innovative strategies and technology can optimize supply chain operations, reduce costs, and enhance customer satisfaction.

Effective data exchange technologies are vital for any business’s success, no matter the role in the supply chain. Comarch’s mission is to empower companies with innovative IT tools that enhance their supply chain processes while supporting them through their digitization journeys.

Comarch EDI, a cloud-based B2B platform, facilitates secure and swift data exchange for essential documents like orders and invoices. You can connect with partners via various channels, while they utilize the Web-EDI version without needing to alter their existing IT setups. Additional features like dynamic EDI messages and automated inventory reports help you reduce supply chain disruptions, allowing you to fully focus on growing your business.

To optimize document exchange in your supply chain, reach out to our experts today and discover how we can improve your operational efficiency.